Mr Schowalter, can large and heavy tractors protect the soil?

Yes of course, it’s not a paradox. The 8RX, which weighs 20t, and I, weighing around 85kg, have something in common: The exact same contact surface pressure. That means: The machine exerts the same pressure measured in kg per square centimetre on the ground as I do, simply because the tractor has a disproportionately large contact area.

This is the theory. Is this also confirmed in practice?

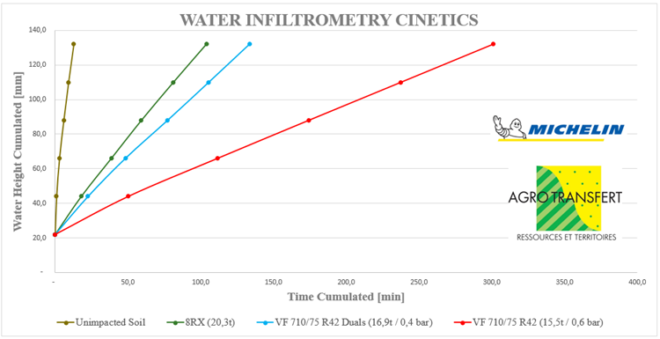

We presented the RX8 as a specialist in soil protection 18 months ago at the last Agritechnica. We have used these past one and a half years very intensively to back up this claim with the help of data from the field and independent experts. We tested 8R tractors in different configurations on a wide variety of soils in various countries and conducted many soil pressure measurements. One of the most interesting results we found was when measuring the penetration resistance into the soil, which can be used to determine whether the soil is loose or compacted. The result: In the tracks of the 8RX, the water could seep away more than three times faster compared to an 8R with single tyres.

This means: Less soil erosion and leaching of nutrients from surface run-off as well as better infiltration, even in periods of drought, and thus a better water and nutrient supply for the plants. All of this leads to more yield, more biomass, and more CO2 sequestration. This is not only good for the environment, but also for the farmer’s wallet. If we get 3% more yield in traditional wheat, this results in an additional profit of over €50/ha (£43/ha) for the farmer.

Ground water absorption capacity after crossing with different chassis concepts: The 8RX (green) performs better than the 8R with dual tyres (blue) and single tyres (red).

The dual tyres also performed well in the tests. Are they a good alternative?

That’s correct. Dual tyres are a good solution. In America, this is no problem at all. There are wide roads, much less traffic and only lax traffic regulations. In much of Europe, it’s a different story. You can’t just drive through the village streets with parts sticking out that are over four metres wide – you’re just not allowed to do that.

In the meantime, there are also new tyre concepts, for example using lower tyre pressures, which enables a larger contact area. Are modern single wheel tires an alternative?

Modern VF tyres and especially tyre pressure adjustment systems are definitely a valuable contribution. This is great for machines which constantly switch between road and field. However, with the load capacity of the tyres, there are limits. These machines do not come close to the level of a dual-tyred machine and the 8RX. Our measurements clearly show this, as do the track depths in the field.

Tires cause a significantly larger wedge of soil that the tractor pushes in front of it. This increases the rolling resistance.

Does the track depth have a significant effect in practice?

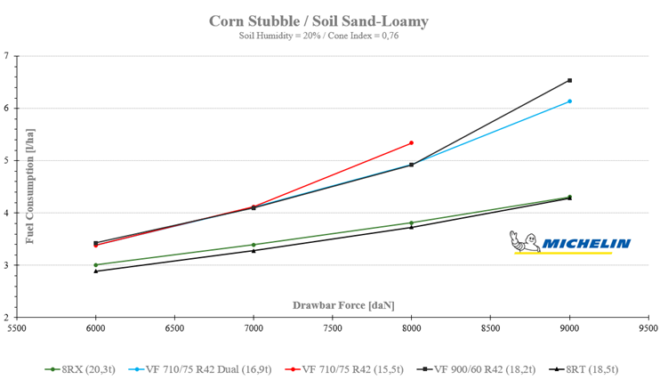

Absolutely! The deeper the tractor sinks, the more ground is “pushed” in front of the tyre or must be crossed. This leads to higher rolling/traction resistance, which in turn increases fuel usage. This is different with the flat tracks of the crawler gears, where fuel savings of over 20% can be achieved.

20% fuel savings, isn’t that slightly exaggerated?

Well, we have already seen it in some demos and the measurement data from Michelin also testifies to that. We got very similar results on three different soils. The higher the traction force the greater the benefit. Four instead of five litres per hectare – that’s the statement. The 20% fuel savings have been achieved here at a traction force of 7,000 daN. The machines do not always operate under maximum load, but these tractors mainly do the heavy tillage, where full traction is required.

The fuel efficiency advantages of the 8RX are already evident at relatively low pulling power requirements. With higher pulling power requirements, the efficiency advantages increase as well.

Is the good result only achieved on flat areas?

No, not just on flat areas. A large part of this saving is also due to the rarely occurring slippage. Tractor wheels typically mesh with the ground with 12-16 lugs: the 8RX with 44. As a result, wheeled tractors typically have slippage values of 8-12% – in practice, often beyond 15%. Tracked tractors have typically 1-3% slippage values. That’s a 10% increase in productivity.

In addition to profitability, sustainability is playing an increasingly important role. How is the efficiency reflected in CO2 equivalents?

That can be calculated quite easily. Depending on the capacity utilisation of the machine and the number of hours it is used in the year, savings of around 20t per machine and year can be estimated.