Although farm machinery accounts for a comparatively small proportion (just 6m tonnes) of total carbon dioxide emissions from agriculture (66m tonnes), we still need to say goodbye to diesel fuels as quickly as possible in order to contribute more to climate protection.

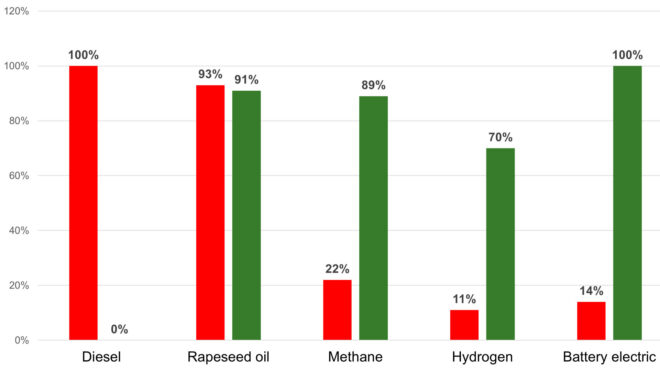

Unquestionably, fossil fuels offer the highest possible energy density that we can use on a tractor. Yet, despite the latest advanced engine technologies, these fuels have the highest CO2 emissions compared to other types of propulsion. For example, a significant reduction in emissions could be achieved by using hydrogen, methane, rapeseed oil or fully electric motors.

However, this positive result is often offset by significantly lower energy density. This means that either the fuel tank or the battery must be significantly larger, or the working time of the tractor, at high loads, is so short that it is not suitable for use as an alternative to traditional machines.

Possibilities and limits of alternative drive systems for tractors

A comparison of different drive types for tractors shows that diesel has the highest energy density but produces the most CO2 emissions. Although alternative fuels like methane, hydrogen or electricity can significantly reduce CO2 emissions, they have a low energy density, and therefore are not yet suitable for powering large tractors. A good compromise is the use of rapeseed oil as fuel.

Electric propulsion is a goal worth striving for

An electric drive would provide high flexibility, lower weight, and a smaller installation space, in relation to the power produced – if we only look at the motor. On the other hand, the batteries themselves are still far too heavy and too low in power to be suitable for widespread use. However, battery technology is expected to make great strides over the next few years.

Biofuels represent a promising bridging technology that is available to use today. In particular, rapeseed oil presents a good alternative, in relation to diesel, as it offers 93% energy density, and emissions savings of 91% (with decentralised generation and consumption).

Battery-powered large tractors are still very heavy due to the batteries’ low energy density, and therefore are still not suitable for practical field use.

Rapeseed oil is a sustainable solution

Rapeseed is grown on many farms. Therefore, the oil extracted from it is readily available to many agricultural companies. Rapeseed cake, a by-product of cold pressing, has a high protein content and is therefore valuable animal feed. A positive side effect is that the rapeseed cake can partially replace imported soyabeans – with all their negative side effects, from cultivation to transport and other costs.

In this respect, rapeseed represents an extremely sustainable solution, provided that the quantity produced covers the farm’s own needs. This is because it only partially competes with food production. This fuel counters the often critical question of “tank or plate” with the answer “tank and plate”.

The multi-fuel tractor can work with diesel, biodiesel, chemically unmodified P100 vegetable oils and hydrogenated vegetable oils (HVO).

Multi-fuel tractor project

Prof. Peter Pickel is the Future Technologies Manager at John Deere’s European Technology Innovation Centre in Kaiserslautern.

However, in order to be able to use rapeseed oil and other biofuels, the machines must be adjusted. The drive system of a tractor has to be modified, in terms of engine performance, exhaust gas treatment, engine lubrication, and starting behavior in cold weather.

At John Deere, we have addressed this challenge with our multi-fuel tractor project. It can work with diesel, biodiesel, chemically unmodified P100 vegetable oils and hydrogenated vegetable oils (HVO). Mixtures of those biofuels can also be used.

Thanks to the installed sensors, the system automatically recognises the fuel being used. In intensive tests – including in co-operation with the Technical University of Kaiserslautern – we were able to prove that the engine works without any performance impairments or additional fuel consumption. In addition, the engine complies with the applicable emissions restrictions – Level V for mobile working machines.