While it may be keeping one boot firmly in the soil with its 330 ewes and its direct sale of farm-raised lambs, the private limited farm (EARL) of Ardilla is also home to some very high-tech agriculture. “We are now able to use variable rates for all our applications,” says Daniel Sous, who has been working on the family farm since 2012.

On the sandy soils of Landes, the Sous family cultivates 400ha, 320 of which grow irrigated maize with yields of 6.5-6.75t/ha. A great deal of time and resources have been invested to improve work accuracy while reducing input costs.

Daniel Sous is pushing site-specific adapted weed control on his farm.

Yields have been mapped for six years, all machines are equipped with RTK guidance and section control is widely used. Only the intra-plot variability still needs to be addressed. “We have just introduced variable rate seeding,” the young farmer reports. “We are in the process of mapping the soils so that we will soon be able to apply PK fertilisers as well as soil improvers at variable rates.” Another current project is precision nitrogen application. On the weed control side, following trials carried out with the support of his local dealer Agrivision, Mr Sous is on the verge of becoming one of the first French farmers to apply chemicals at variable rates for weed control.

Over 180 third-party software products

You want to maximise your crop yields?

Visit the John Deere smart farming solutions website to learn how our precision agriculture technologies can help you with everything from high speed mechanical weeding to precise application of chemicals and fertiliser.

For quite some time the Operations Centre platform has been open to third-party software, in order to centralise digital tools for farmers and allow a smoother data exchange, while resolving compatibility issues. More than 180 companies are already offering their solutions via the “more tools” function available in the Operations Centre. Recently, the Toulouse-based drone manufacturer Delair integrated a weed recognition service with weed control recommendation maps.

Looking for a producer equipped with precision technology to test its new service, Delair approached the farm through the John Deere dealership. Always on the lookout for innovative solutions, Mr Sous did not hesitate for long. “We mostly have datura (part of the nightshade family), but our weed pressure is normal,” says Daniel. “We were able to take a chance and try it.”

As a result, the farm made 42ha available for the trial. In cooperation with Delair, they decided that variable rate spraying would be more effective for the second herbicide application. Following the first application across the whole area, half was treated with a full dose at the four-leaf stage. At the same time, Delair flew its drone equipment over the remaining area.

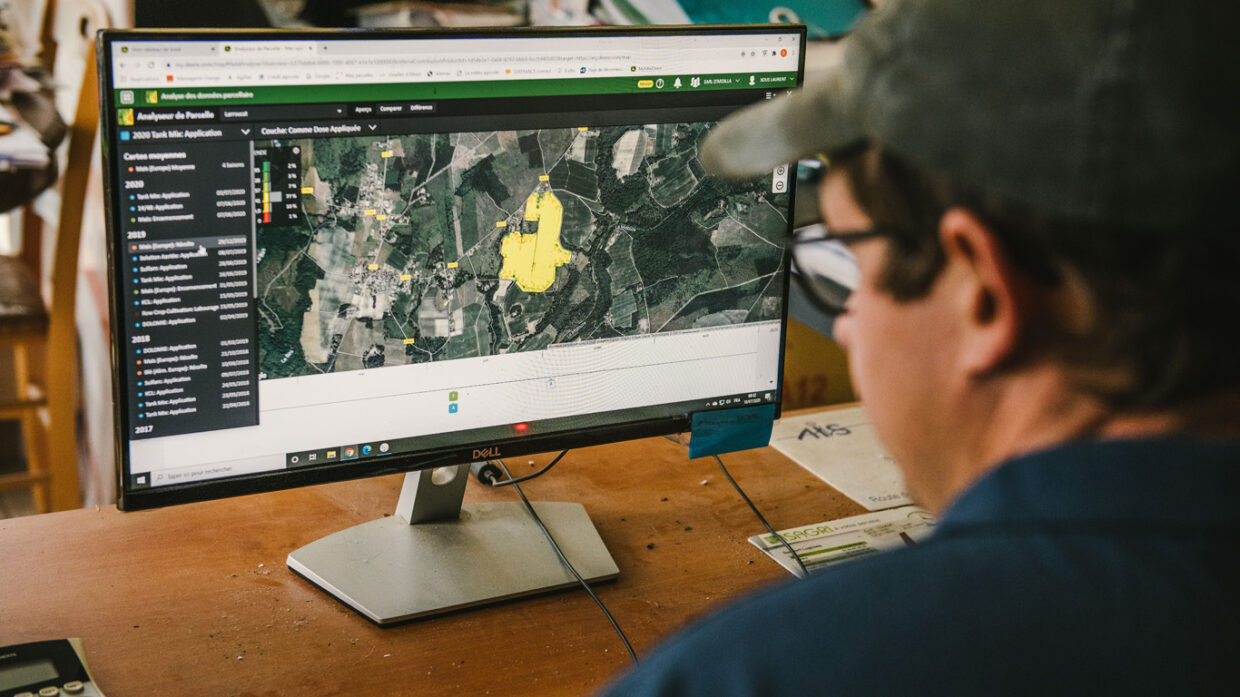

Daniel Sous sends setup files and application maps wirelessly from the Operations Center to his machines – once there, he then selects them for the field to be processed on the display. The machine adjusts the application rates automatically and depending on the location.

Section controlled spraying

The recommendation arrived three days later, allowing time to process the data. “The map was imported into the Operations Centre,” says Mr Sous. “The special feature is that it determines the exact quantity to be applied. I ordered the product, filled the sprayer and left. After spraying, I was right on cue. There was no need for more or less spray.” The herbicide savings, compared to the area treated at full rate, was 50%. Nevertheless, at the time of harvest, 97% of the plot was clean. “Beyond the savings on active ingredients, we also have to take into account the time saved and the reduction in diesel fuel,” the farmer points out.

I ordered the product, filled the sprayer and went. It was a perfect fit when I applied it.

Daniel Sous

Alexis Janson, Delair’s agriculture and forestry engineer, wasn’t surprised by the result: “The trial was particularly successful,” he says. “We’ve been working on our algorithm for four years so the test at Mr Sous’s farm was mainly for demonstration purposes. It was also for us to see how the client experienced the data processing chain and to evaluate the effectiveness of implementing the recommendation with existing equipment.” Including the cost of the service (drone flight and data processing), Mr Janson estimates the average saving on the second herbicide application in maize to be 30%.

Other trials are also being conducted in crops with narrower rows like oilseed rape, sugar beet and even cereals with “very encouraging” results according to Delair. It believes that it will soon be able to offer an operational service on these crops. Currently, the imaging is only capable of delineating the weed population in a block, but finer distinctions should be possible in the future. “The next step will be species differentiation. Our vision for the future is to be able to vary the dosage according to the plants. This will, however, require individual nozzle control.”

The Sous family: daughter Sarah, parents Clotilde and Laurent, and son Daniel (from left). In addition to farming, the family keeps sheep of the Berrichon de l’indre breed.

The environmental issue

This is just one of the Sous family’s investment projects. “The only thing we could have improved was the responsiveness of the section control, because we were operating with 3m sections,” says Mr Sous. “That’s where the missing 3% on weed control came from. That will get better as soon as we can control each nozzle individually.” The outcome of the test remains “very positive,” he adds. “I am seriously considering using this service in future. This will change the way we work on weed control.”

While the primary goal remains economy, the farmer is well aware of the sustainability and image issues. “Everyone knows we’re going to be asked to apply less product in the next few years, so we have to keep that in the back of our minds. The idea, under these conditions, is to maintain the same weed control efficiency while saving costs.”

Tools adapted to needs

Ulrich von Stael, product marketing manager for AG Management Solutions at John Deere, emphasises this: “This is just one of the solutions we offer in the Operations Centre, but Delair is a particularly good example of how opening up this platform will enable us to offer our customers systems that are diversified and adapted to their needs.” As a result, users can customise the Operations Centre by adding additional functions to suit the day-to-day running of their farm.

“Any exchange of data between the Operations Centre and the connected software companies is fully controlled by the data owner, either manually or by accepting an automatic data synchronisation system,” says Mr von Stael. In addition, it is expected that the number of software products available in the platform will increase rapidly by 2021: “More and more external service providers see the benefit of integrating their solution into the MyJohnDeere environment. In the end, the farmers are the winners.”