We have made a huge leap forward over the past two years.” Florian Straten greets people at the LVD Krone dealership office, in the municipality of Spelle in the north-west of Germany. A livestock farming region, where maize alternates with grassland. “There was a time when front-axle suspension or air-conditioning were optional features,” smiles Mr Straten. In a few years from now, guidance systems will undoubtedly become a standard feature. On the dealership’s machines, it is already pre-integrated and ISOBUS ready.

Today, 70% of the firm’s customers use equipment with guidance systems, reveals the AMS expert. And this standardisation brings with it a deeper evolution of practical applications. “Every customer who purchases a tractor creates an account in the Operations Centre. From that moment, the machine itself begins to document the plots. The customer chooses to use this information or not, but the database is already there.” As a result, the step towards switching to precision farming has been greatly reduced.

This regional trend reflects a more general one, in Germany as well as in Europe. Digital tools become attractive when it comes to renewing equipment. The resale price and compliance with environmental standards are just some of the positive arguments. However, connected agriculture does not only mean connecting the machines, but also the stakeholders. In this new green revolution, “dealerships are an essential link between the developers of technologies and those who use them,” summarises Mr Straten.

Contractor Ingo Janssen in conversation with Florian Straten.

Field support

farmer left with it and, unless a problem arose, we never saw him again. Today, with precision farming, the subsequent follow-up support is much more sustained.”

There are, of course, some obstacles that dealers must help users to remove, like compatibility issues. “Customers have fleets composed of various types of equipment. So, the data flow factor becomes relevant.” To optimise matters on farm, interaction with colleagues from other brands is useful, says Mr Straten. “Certainly, the Operations Centre is changing very quickly. We can read and transfer most formats.”

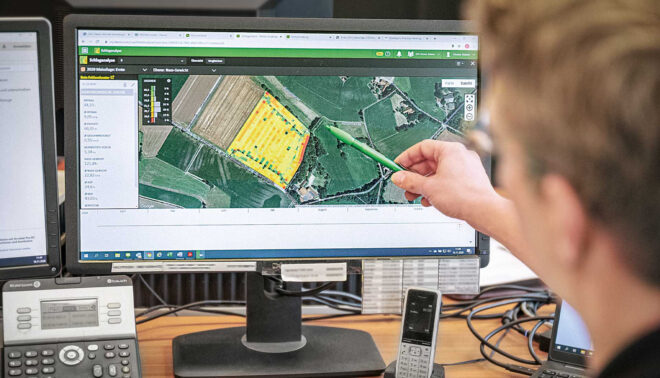

Another consequence of the digitisation is that dealership support is more closely integrated with the physical farming practices. Mr Straten describes exchanges that go beyond the machinery aspect: “When we work with the client in MyJohnDeere, we go into greater detail about their cropping systems. With the application maps, the discussion moves to the agronomic aspects of the land. For example, we need to tell them: ‘Look, you have used the same seed density for the past 20 years, we can optimise it to increase the yield’.”

Stand out from the competition

In deploying these new tools, the dealerships can count on a strong ally, says Mr Straten: “Agricultural contractors are another essential bridge between the equipment manufacturer and farmers. It does not really matter what we as dealers tell the farmer. When they see that their service provider already has the technology available, and what they are doing with it, they become much more inclined to equip themselves with this technology.”

A lot of our customers switch to precision farming each year.

Florian Straten

So what is the contractor’s view? “This is an extremely competitive industry,” explains Ingo Janssen, head of a family business founded in 1958 (more than 30 salaried employees and 25 seasonal workers). Today, like before, reliability and work power remain the essential business criteria. “But that is not enough to stand out. You also must be a force for innovation. What makes me, as a contractor, more useful to the customer than the competition? Smart farming is predestined for this, so to speak.”

Through this reflection he became interested in the Cultan technique (Controlled Uptake of Long Term Ammonium Nutrition). The principle is to deposit ammonium in rows to a depth of 50mm, using discs fitted with injectors. Ammonium, unlike nitrates, does not leach out, but attaches itself to soil particles; therefore 10-20% of fertiliser can be saved. This method also promotes root growth, a plus for yields in the face of water stress. When using this method Mr Janssen applies site-specific ammonium based on available field information.

For Florian Straten, traders are an indispensable link between the developers of the technologies and those who use them.

Simplify the work of livestock owners

Here too, digitisation is changing the relationship between operator and the service provider, as the contractor is more involved in the decision-making process. “We cannot implement recommendations without communicating with the customer on the purpose of the operations,” says Mr Janssen. This therefore also means providing agronomic advice. An essential part of his job is to maintain “a network of experts, whom I can call on with specific questions.”

In this region, largely dominated by livestock, where “money is earned in the barn”, the switch to connected agriculture is most often made at the contractor’s initiative. For Mr Janssen, convinced of the importance of this approach for the sector, it is a question of being proactive. “The livestock farmers are already overwhelmed with work, and do not want to take on additional loads by adopting a new technology. However, they are happy when a new method optimises their forage production and effluent management.”

The most popular precision service is the spreading of slurry. The self-propelled Vervaet Hydro Trike is equipped with a Harvest Lab 3000 sensor, whose near-infrared sensor measures the nutrient content of organic fertiliser 4000 times per second. The working speed is used to control the dose, providing the key to a possible increase in yields, and subsequent savings in mineral fertiliser usage. “This year, we had a case where the Harvest Lab showed abnormal values, not consistent with the analyses carried out beforehand,” says Mr Janssen. “After discussion with the farmer, it turned out that the slurry had not been properly mixed on farm.” This kind of adjustment would not have been possible without feedback from the contractor.

Cards on the table

In the end, “the operators see the advantage of spending a little more to have another degree of security in the planning,” he notes. “Starting next year, we are getting ready to provide customers with precise information on the amount of energy available in their forage stocks. If, for example, I have sown 45ha and the energy of 40ha is sufficient for the operation, I may decide to sell the excess, rather than storing it.”

In customer relations, the emphasis is on transparency: There is no question of trying to tout a miracle recipe. “As a contractor, I find it dangerous to promise a 10, 20% yield gain. We start from the potential of the soil, to represent the possible levers for action, such as variable rate sowing, and make the customer understand why he can hope that the undertaken measures will bring better growth.”

Even without going so far as to predict dramatic increases in productivity, saving on seeds, or other inputs, this is a way of influencing the margin, the usefulness of which is obvious to the farmers, he emphasises. “The practical benefit of the service must, simply put, be well explained.” The company organizes B2B evenings with up to 250 farmers every year. The working methods are presented on a large screen. These events have become a tradition and have boosted the adoption of the methods.

A mastered technique

With the growing complexity of the new tools, dealerships’ training roles have grown in recent years, points out Adeline Vacossin of the PM-Pro dealership in northern France. Recently, the dealership has been a service provider to the Chambers of Agriculture, within which it organises educational sessions on precision agriculture. The content includes a refresher on guidance systems, and discussions on the implementation of section control, variable rate application, cartography, RTK (Real Time Kinematic) guidance, and surveying.

Covering an area with a radius of more than 200km, PM-Pro employs seven FarmSight field experts, who can provide tips and tricks. “The heart of our business is to reassure customers that we have fully understood our own tools, to provide reliable information, and to assist them in these new technologies,” says Ms Vacossin. A rewarding mission every day. For the young woman, who came to the agricultural sector because of her passion for nature, the stake goes beyond complying with environmental standards. “These technologies offer an opportunity to respond to the ecological challenge, without endangering the viability of farms.”

As well as answering questions on how to simulate the position of the machine in a curve or properly manage section control during headland turns, Adeline Vacossin also organises training on precision farming.

Variable rate application training

Farming in Chouilly, Nicolas Cuvillier (51) describes the very close working relationship with his dealership. “The trust is high,” he testifies. On the 220ha which comprises the two family farms, he and his wife grow wheat, spring barley, dehydrated alfalfa, beetroot, grain maize, and 3ha of grapevines. The latest investments were a fertiliser spreader and a sprayer equipped with section control. “I was lucky enough to be able to undergo variable rate application technology training in January 2020, on the advice of my sales representative.”

I was lucky to be able to undergo variable rate training.

Nicolas Cuvillier

The soils are extremely variable. “The harvester’s yield sensor shows big gaps between the top and bottom of the fields. It is not necessarily the bottom which is better.” Very poorly distributed rainfall in recent years has led the farmer to consider using optimisation measures. So during the previous season, he started to work with satellite biomass maps, provided by Farmstar.

“To implement variable rate application, training is necessary, but it does not present any particular difficulties.” The application maps arrived at the farm in RX format, so they needed to be converted for compatibility with the console. In addition, precise knowledge about the hardware, the type of console, and the products and inputs being used is required. “Once this is set up and you have learned how to handle it, you no longer have any doubts,” explains Mr Cuvillier.

Nicolas Cuvillier, a producer from Chouilly (Département Marne), maintains close business relations with his dealer.

Working more cleanly

Last year the third nitrogen application in wheat was delivered at variable rates based on biomass maps. “The recommendation showed deviations ranging from zero to 80 units. This clearly indicates the over-fertilisation levels in certain areas, and under-fertilisation elsewhere.” Wheat yielded more than 1t/ha higher in the last harvest, following favourable weather conditions. A good result that Mr Cuvillier also attributes to the precision of the fertiliser. “If we compare the recommendations and the yield map we got from the combine, we can clearly see the gain in efficiency coming from variable rate application.”

He concludes: “I absolutely do not regret implementing this technology.” The operator points out that dialogue with the equipment dealership is now more frequent and has improved. His PM-Pro sales representative visits him every week. “Today there are specialists at dealerships that were not there before. At my dealership, there is a guidance systems expert, a telemetry expert, etc.” In training rooms, in the workshop, in the store; the dealership is also a place for discussing the use of equipment and new technologies with other customers. “This is what keeps everyone moving forward in implementing these technologies.”

Better data exchange

Data compatibility has been a big challenge in precision farming, but manufacturers are implementing better co-ordination. As an example, the Dataconnect solution now enables communication between the John Deere Operations Centre, Claas Telematics and 365FarmNet platforms, for location, machine progress, fuel, work rate, harvest logistics, etc. New Holland, Case or Steyr machines are also visible. Learn more about DataConnect at deere.uk.