As of mid-March 2020, many city, and indeed country, dwellers have found themselves in a situation that is both unusual and unprecedented as a result of the Covid-19 virus. People have had to change their routines from one day to the next as they are often only permitted to leave the house with good reason. A good reason: Buying groceries.

It is precisely in this area that consumer behaviour is changing quite significantly, and in many western countries, the demand for local produce is growing. For farmers, this is an excellent opportunity to reach consumers directly.

We talked to Dr. Hans-Dieter Stallknecht of the German Farmers’ Association, who told us: “It is still too early to identify a clear trend. One thing is certain though: Consumption patterns are going crazy. If you have space and capacity, you can position yourself in the market very well at the moment.”

There is talk of adapting both farming and sales towards direct marketing, to provide a safe alternative to supermarkets. The Furrow has been visiting farms in Germany, France and England, all of which are trying to make the best of the current situation.

Germany, Vaihingen an der Enz:

Organic crates from the Braun farm

Michael Braun notices a significant increase in demand in his organic farm in times of Corona.

“It’s totally nuts. Because of corona, everyone is buying German produce now, especially organic,” says Michael Braun. He took over the Braun organic farm in Vaihingen an der Enz from his parents 34 years ago. Today, a variety of salads, vegetables and herbs, as well as grain, pumpkins and sweet corn, grow on 65ha of arable land and in 5000m² of greenhouse.

Since 1988, the company has been supplying private customers, companies, schools and kindergartens with food crates. When the Covid-19 virus arrived in Germany in March, more and more people ordered the organic crates. Since then, the packing station has been in a state of emergency. The employees were rapidly unable to keep up with orders. On 9 March 2019, one week before schools in Baden-Württemberg closed, the company consequently stopped accepting new customers. “This has never happened before in my entire career,” says Mr Braun, still surprised.

3,500 organic crates a week

Today, the organic farm supplies up to 3500 customers a week. This is 10% to 15% more than usual. Sales have risen by 50%. In order to process the additional orders, crate packing now runs on a two-shift basis three days a week. It’s now possible to pack for 12 to 14 hours a day. 50 permanent employees are supported by students and school children.

Hygiene measures are also implemented and maintained in the packing line.

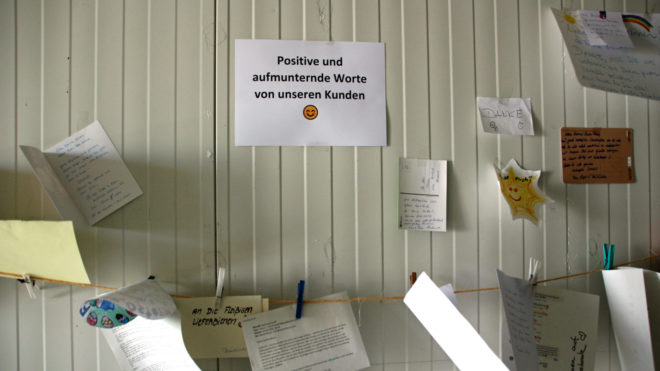

The drivers deliver the crates without customer contact. Clients have been really receptive to this new approach. Most of them are not at home when the goods are delivered anyway. “We have very specific parking agreements. Many have given us a latchkey so that we can leave the delivery in the hallway,” explains Mr Braun. Customers can purchase insulation boxes so that the food stays fresh in front of the house. And while contact is avoided during the delivery, it is unexpectedly added elsewhere: Many customers write cards and letters, even painting pictures to thank the organic farm for its work. That’s encouraging.

A lot of work during Corona

Mr Braun wanted to thank his employees, so he paid them a Corona bonus as early as March: More than €2.50 (£2.23) an hour. “This is to compensate for all the hard work they’ve done. We have a great team of employees,” he explains.

There is some uncertainty despite rising sales. Although the company has enjoyed stable growth of between 7% and 10% in recent years, if the situation continues, customers could drift away. “I realise that our products can be replaced by cheaper ones,” explains Mr Braun. He has planned a warehouse extension for new offices, packing lines and cold stores. Approval was granted three weeks ago, and everything is ready for construction to begin. “We’re looking at it positively at the minute and I think we’ll build. Investments are always a risk. You just hope it will go well.”

Additional information can be found here:

France, Grigneuseville:

Business is booming for the Blondel butchery

Sophie and Olivier Blondel currently process 50 orders per day instead of the usual ten.

In Grigneuseville in Normandy, Sophie and Olivier Blondel keep 3000 pigs, most of which are fed on the farm’s cereal crops. Since 2015, they have expanded their processing plant so as to offer pork by direct sale. Under the brand “J’adore le cochon” (I love pork), the Blondels sell fresh, smoked and some processed meats – pies and stews, for example.

We have seen the demand for our products increase by almost 50% since the beginning of the corona crisis.

Olivier Blondel

“We have seen the demand for our products increase by almost 50% since the beginning of the corona crisis,” says Mr Blondel. “A third is sold on site at the farm shop, the rest in local farmers’ shops. At present we only sell to individuals, because since 16 March and the start of the lockdown in France, visits to restaurants are no longer possible. Part of the people now buy directly from the producer. Here they can shop without having to stand in line at the supermarket,” he adds. “We’ve hired an extra person for our processing plant and a temp for our store so we can process 50 orders a day instead of 10.”

Protection for customers and employees

Since 2015, the Blondels have expanded their processing plant to be able to offer the pork by direct sale.

Precautionary measures were easy to put in place: The checkout area is now protected by Plexiglas and hand disinfectant is available for customers and used in the butcher’s shop as well. “Since we’ve been lucky with the weather this spring, the shop door is open all the time so that customers do not have to touch the door handle,” says Mr Blondel. “At one metre wide, our meat counter is perfect for maintaining the minimum distance between customer and seller. In the future, we want to sell masks in the store as well.”

The couple currently slaughter and process an average of 45 pigs per week. The pigs are mainly fed with the grain from their own farm, supplemented by rapeseed, peas, broad beans and soybeans. “I’m a farmer and have gained practical knowledge of butchery at a secondary school for the dairy and meat trades in Aurillac,” says Mr Blondel. “Afterwards, I was able to acquire in-depth knowledge in about twenty different companies before finally starting my own business.”

With over 100 products, the “J’adore le cochon” range is quite versatile. “Our manufacturing principles revolve around three pillars: Traceability, freshness and flavor. For us it’s very important that no dyes, preservatives, flavorings or yield enhancers are used in our processes. Here you get the authentic taste of charcuterie.”

Additional information can be found here:

Great Britain, North Yorkshire:

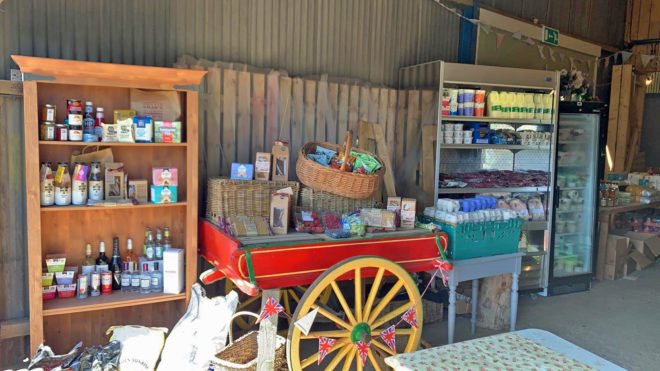

“Drive-in” at the Bert’s Barrow Farm Shop

Even in Corona times the farm shop Bert’s Barrow supplies its customers with fresh products.

As a result of the imposed curfew, rural businesses across the UK are restructuring their activities – but the best ideas often emerge in times of crisis. One farm shop in North Yorkshire has adapted to provide a safe alternative to the supermarket.

Bert’s Barrow Farm Shop, Hillam, near Selby is providing vital support to the surrounding community with the successful launch of a drive-through shopping service, giving customers access to affordable, local produce without having to leave their cars.

Since April 2020, business owners Jason and Charlotte Wells-Thompson have been operating their drive-in shopping service, together with a team that selects, packs and receives payments from 50 customers per hour.

Contactless shopping

“Difficult situations can really force you to get creative and be resourceful,” says Mrs Wells-Thompson. “The weekend before the lockdown was announced, we had a surge of customers. It was chaos and we soon realised it wasn’t possible to remain open as a shop observing the correct distancing rules,” she explains.

“Other companies offered delivery services, but we lacked both the transportation and the time. We still needed the customers to come to us, and the drive-through allowed us to do that while minimising social risk.” In only three days, the couple put the plan into action.

The customers thank for the service in times of crisis – contactless of course.

So how do they run this new business format? “With a completed shopping list, customers drive their vehicle to our farm shop, signs instruct them what to do to keep us all safe,” explains Wells-Thompson. Orders are taken at the till through the closed car window, the team pick out the produce and take payment using a contactless receiver. “We can keep the car window up and take multiple payments for orders over the £45 transaction limit.”

Finally, the team load the shopping into the customer’s boot, pre-opened by the customer before reaching the service area to reduce the risk of cross-contamination. The family have also maintained a front-of-house by using the old potato store as a shop front and service area.

Blogs entries for inspiration

Mrs Wells-Thompson explains: “We can’t have people in the farm shop, but we still want to provide a visual shopping experience. After all, there aren’t that many opportunities for them to leave the house at the moment. So why not make a change for once?” Bert’s also provides variety with recipe blog entries tailored to the vegetarian crates.

Due to booming business, the couple increased their team from three full-time employees to 12 full- and part-time employees and some volunteers. “One of our staff members would usually be supplying events with entertainment equipment, while another is a professional falconer – both lost their income because of the current crisis,” explains Mrs Wells-Thompson. “It’s very much a team effort – everybody is valued, and we couldn’t do it without them.”