A combine consists of almost 20,000 parts. It is a technological powerhouse which must withstand the most diverse operating conditions around the world.

In the final assembly hall at the John Deere plant in Zweibrücken, machines that are precisely tailored to customer requirements roll off the production line every day.

But how is such a machine actually put together?

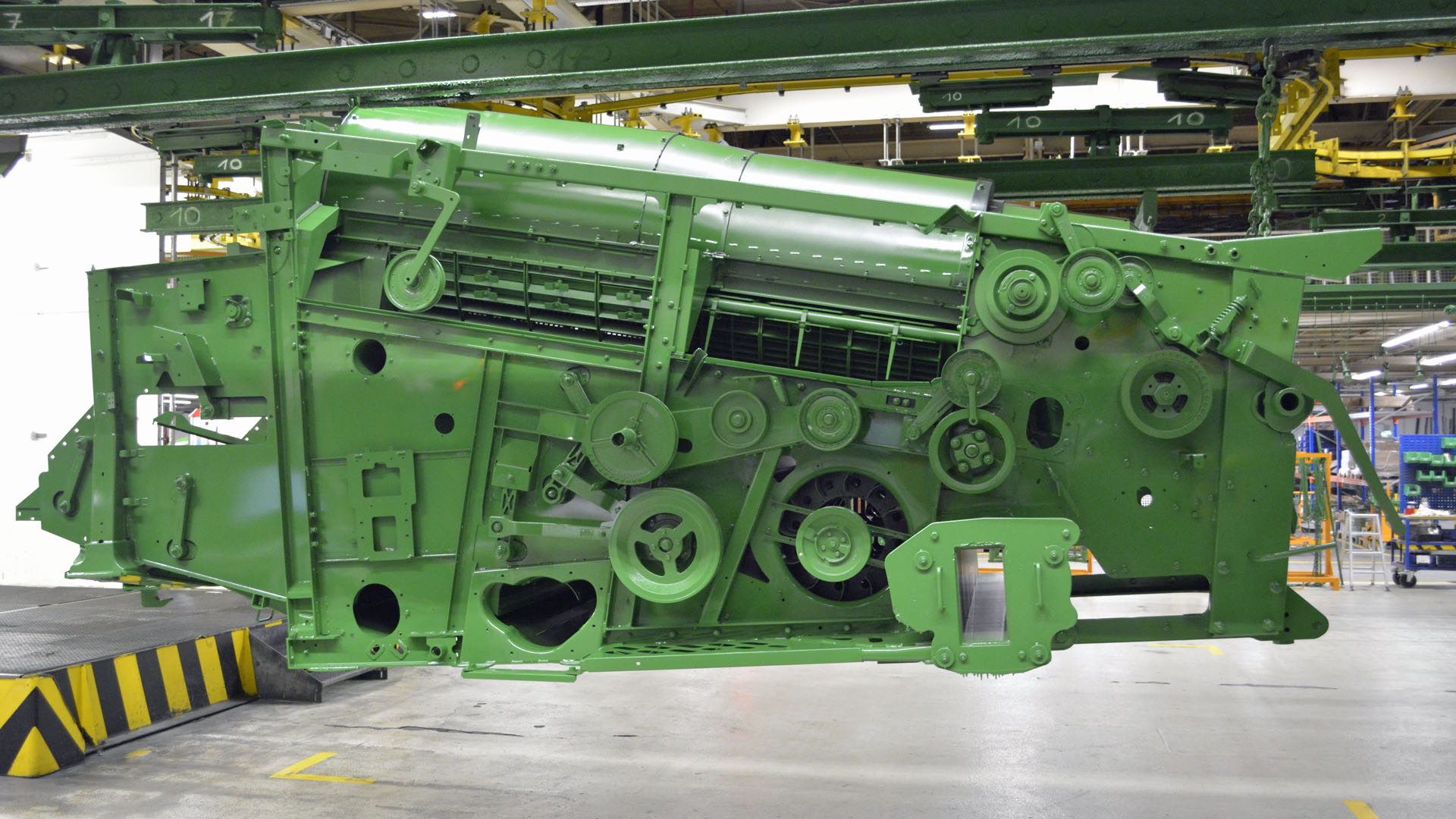

Step 1: The body comes from pre-production

The starting point for the final assembly is a solid, welded frame – internally referred to simply as the ‘body’. The threshing unit has already been fitted, the side walls welded, and the first components integrated. The body is the foundation of the combine and comes directly from pre-production, including the paintwork. Every machine starts in the same way and is developed individually from this point onwards.

Step 2: The ‘marriage’

Two assembly lines converge in the so-called East Hall. On one line is the body, on the other the grain tank which collects harvested grain. The two components meet at a precisely timed point and are connected. This moment is known as the ‘marriage’. From here, the combine begins to take on its final shape.

Step 3: On the main belt

The connected body shell is now placed on autonomous transport vehicles, known as dollies. These drive the combine through the final assembly hall step by step. Station by station, the machine continues to grow – always under the watchful eyes of the assembly teams. Various conveyors transport the individual components, which have been prepared elsewhere, onto the main conveyor towards the final assembly of the machine. Every cycle is meticulously planned, yet flexibility is still required because no two machines are the same.

Step 4: The cab is assembled

The operator’s cab comes pre-assembled from the John Deere plant in Bruchsal, Germany. It is placed onto the machine body using special lifting devices. The cab is not just a workstation, but a high-tech control centre: Displays, controls, and camera technology are fully integrated here. Depending on the equipment, the interior fittings vary considerably – from the basic version to the fully automated premium cab.

Step 5: The engine is installed

Depending on the model, the engine comes either from the US plant in Waterloo or from the French plant in Saran. The powerful units are selected and assembled to order. The engine not only drives the vehicle but also supplies many other components via a complex hydraulic network. This requires maximum precision, as the combine will later be working under full load.

Step 6: Assembly of the inclined conveyor

The inclined conveyor is the link the header and cutting platform to the rest of the combine. It is precisely connected to the chassis, as it directly influences crop pick-up. Even the smallest deviations would affect the harvest performance.

Step 7: The filling station

At this station, all the necessary operating fluids are filled: Hydraulic oil, coolant, windscreen washer fluid – everything is dosed automatically. The systems are paired to the machine monitor, ensuring that exactly the right quantity is provided for each model. Modern sensor technology ensures real-time control and prevents incorrect filling.

Step 8: Commissioning

Now it gets loud: The machine is started for the first time. Among other things, the hydraulic systems, tightness, calibration, and the mobility of the mechanical components are checked. This station requires experienced employees with a trained eye for the smallest irregularities. Even the littlest errors can lead to high downtime costs during harvest.

Step 9: Completion

Now it’s time for the final touches: Cameras are mounted, plastic trim panels attached, and large decals affixed – with millimetre precision and without bubbles. Filigree craftsmanship at the highest level is also evident here. These final details make the difference in the appearance – and are also a promise of quality to customers.

Step 10: Ready for the customer

When the combine leaves the hall, it is ready for worldwide use – individually configured, manufactured with the utmost precision, and rigorously inspected. For assembly manager Jan Braunhardt, this moment is still special even after many years: “When such a giant rolls off like that, it’s impressive every time”.