Mr Kreutzer, what is your role at John Deere and how did you come to work in this role?

I come from an agricultural holding near Diepholz in Lower Saxony. As the eldest of four, after school I decided not to take over management of the farm; it is now run by my two brothers. Instead, I studied geoinformatics. That’s when I was given the opportunity to work with GPS and GIS systems and was inspired to go on to work for John Deere in the precision farming sector.

In 2005 I completed my thesis on the topic of section control at John Deere’s site in Zweibrücken. At that time, I was working in the testing department. After working in different stations within John Deere, I am now responsible for the so-called digital applications. These include the mobile apps and the the Operations Centre web application. I also still have a close connection with my family’s farm. When I’m there, I can test out the new technologies in the field.

What does precision farming look like on your family’s farm?

As I am so passionate about this area, we started working with new technologies very early on. For example, in 2000, we were one of the first businesses in Germany to have yield recording on our John Deere combine. A lot has happened since then.

Now all our tractors and combines have AutoTrac.

Now all our tractors and combines have AutoTrac. We also use the yield mapping options, drive using section control, document our work in detail and are starting to use site-specific management. Our business is a processing plant. We rear 10,000 pigs per year and operate a biogas plant along with other farms. It is therefore especially important for us to optimise the nutrient flow in-field and on the farm.

How do the mobile apps actually help you on the farm?

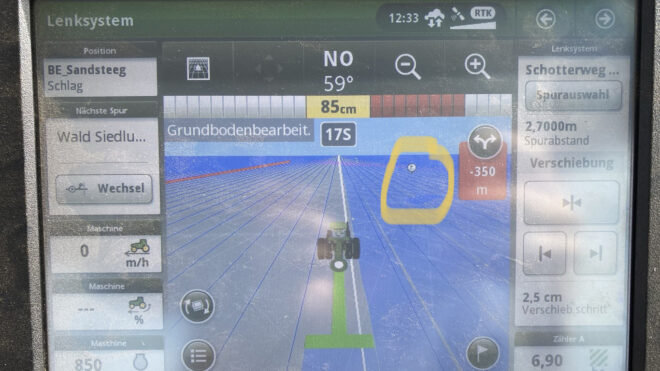

In der mobilen App markierte Torsten Kreutzer ein Hindernis, auf der er auf dem Feld gestoßen war.

Like many other people, we are using smartphones more and more. In the MyOperations Mobile App, for example, I can see the error codes of a machine in real time. This was very useful recently when we chopped crop for the biogas plant. Diesel had just been delivered and my brother was the first to refuel. There was probably a little dirt in the tank, so the diesel filter closed and the power failed. I received this error message directly on my phone and sent a screenshot to our dealer via WhatsApp. He put a new filter out for me and after half an hour I was able pick it up. That was at 7.30 pm on a Saturday.

The app has also already prevented major damage to machinery on your farm. How was that?

That was in the early summer of 2020. As it hadn’t rained since March, the ground was very dry and we were going over with a deep cultivator, without ploughing the soil. The cultivator goes 30cm or more into the ground. I was sitting on the tractor when there was a quick “clack” sound behind me and I saw that three of the cultivator tines were sticking up. It was obvious that there was a large obstacle in the way. I used the app to document the location with a marker and GPS position: Stone warning! As the maize seeder was travelling directly behind me, we didn’t have time to take a closer look at the obstacle at the time.

The maize cultivated on this land then went directly into the biogas plant silo in October. Rye should be grown next in the crop rotation. So we choppedand ploughed directly behind so we could drill the rye the next day. Thanks to the marking function, we knew exactly where we had to watch out for the obstacle. Instead of driving at full speed, my brother drove slowly over the problem area. Even then, the obstacle still caught two of the plough’s shear bolts. However, if he had driven at full speed, the entire plough could have been ripped off. By using this feature, we avoided a huge amount of damage.

How could your brother know where the problem area was when he was driving the tractor?

Go Operations Center

Schedule your work in advance and send job information directly to each machine.To the Operations Center

The information that I documented with the app was immediately synchronised with the Operations Centre. Throughout the season, I distribute all the information documented in the Operations Centre back to the machines via setup files. The markings, for example, are then shown directly on the machine displays. This allowed my brother to see exactly where the problem area was when he was ploughing. Information is transferred from the Operations Centre to the machines either wirelessly via JDLink Connect or via a USB stick.

And what will happen to the obstacle?

As soon as the field has been harvested next summer, we will drive out with the excavator and take a closer look at it. It must be quite large because it caught several shear bolts at once.

Short tutorial about setting flags in the mobile app: