The goals of the trial were to optimise NUE, improve application timing, understand the application of the John Deere HarvestLab sensing technology and increase profitability. But why is optimising nitrogen use so important? “Nitrogen fertilisation accounts for 20-40% of crop production costs,” explains Dr David Purdy, Territory Business Manager at John Deere UK. “If there is too much nitrogen left in the soil, it might lead to lodging and harvesting problems, as well as losses in soil carbon due to the relationship between carbon and nitrogen. Furthermore, excess nitrogen can leach through the soil profile to the environment in different forms, for example, as nitrous oxide (N2O) or nitrates, which can be harmful.” Finally, farmers might be prosecuted for environmental pollution in some circumstances.

Team and method

NUE measures how well a crop uses nitrogen. It compares how much nitrogen the plant takes up (the output) to how much nitrogen was available to it (the input – what was already in the soil or applied through fertiliser).

With help from Carl Pitelen, Innovations Manager at the John Deere dealer Ben Burgess, Norfolk farmer James Goodley began setting up the first test site during the 2022/23 growing season. The trial is now in its third year, with two further fields selected during the 2024/25 season. The first field, called ‘Tivans’ was ploughed and drilled with a power harrow, while the second field, called ‘Footpath’ was direct drilled without tillage. Both fields have sandy loam soil and were sown with wheat.

Trial set-up

Both fields received five different treatments:

- Zero nitrogen as a control (NoN)

- 160kg N/ha, which is the desired farm standard (160FS)

- 160kg N/ha plus a micronutrient package consisting of iron, manganese, molybdenum, copper and zinc, many of which play an important role in nitrogen use in the plant (160+micro)

- 220kg N/ha, which is the current recommendation and farm standard (220)

- An application based on recommendations from the Framework for Improving Nitrogen Efficiency (FINE), comprising 230kg N/ha for ‘Tivans’ and 205kg N/ha for ‘Footpath’. (FINE 230 / FINE 205)

The FINE experimental design was developed by Clive Blacker and Joe Walters, both from the project partner DataBaler. “The project is supported by Innovate UK,” says David. “When applying nitrogen, they look at the crop growth stage and soil conditions, with a special focus on soil moisture. Integrating this approach into the field trials has been very helpful for us.”

Importantly, each of the treatments was replicated and randomised three times. Data to estimate the NUE was mainly gathered by drone flights, the John Deere HarvestLab near infra-red (NIR)sensor mounted to the combine, a Soil Plant Analysis Development (SPAD) measuring device and soil samples, as well as manual measurements like plant counts.

The results

For the analysis, nitrogen input and output data were uploaded into the Agronomy Analyser. This is a tool that allows geo-fenced plots to be created in a way that all inputs and outputs are precisely collected, avoiding the need for specialist trials equipment like a plot combine. This software tool was developed by John Deere and is used locally by Ben Burgess while leveraging the existing technology and machinery available on the farm.

The average yield of the ‘Footpath’ field (7.43t/ha), which was not tilled, was about 6% higher than the cultivated ‘Tivans’ field (7.02t/ha) despite the 207kg/ha fertiliser application to ‘Footpath’ being almost 11% lower than to the 232kg/ha applied to ‘Tivans’. At the same time, the measured nitrogen supply from the soil was 56kg/ha for ‘Tivans’ compared to 71kg/ha for ‘Footpath’.

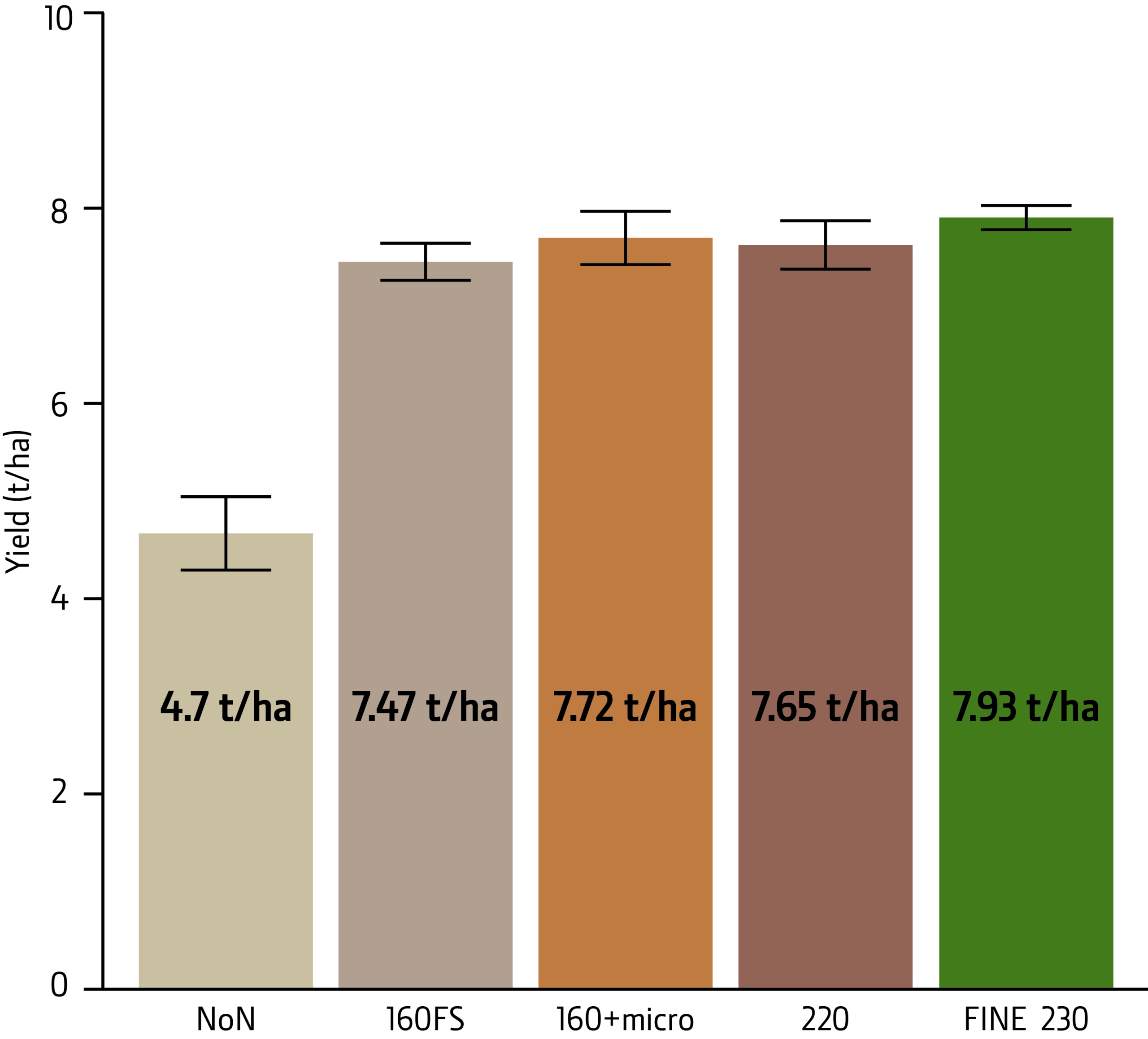

Looking at the yields of the different trial set-ups, unsurprisingly, the yields were lowest in the zero-nitrogen fertiliser plots, delivering 4.70t/ha in ‘Tivans’ and 4.93t/ha in ‘Footpath’. In both fields the FINE treatment, with specific nitrogen application timing, delivered the highest yields (7.93t/ha in ‘Tivans’ and 8.67t/ha in ‘Footpath’).

The second highest yields occurred in the 220kg/ha N-treatment plots (7.65t/ha in ‘Tivans’ and 8.08t/ha in ‘Footpath’). In the plots which received both 160kg/ha N and the micronutrient package, there were higher yields in both fields (7.47t/ha vs. 7.72t/ha for ‘Tivans’ and 7.58t/ha vs. 8.01t/ha for ‘Footpath’). When it comes to crude protein content, it increased with the amount of nitrogen applied in both fields, as well as with the micronutrient package. However, in the FINE plot, it was slightly higher in the ‘Tivans’ field than in the ‘Footpath’ field.

The crude protein content was lowest at the zero nitrogen control trails with only 9.5% in the ‘Tivans’ as well as in the ‘Footpath’ field. This highest crude protein content with over 12% was measured under the high nitrogen fertilisation regimes at 220kg/ha respectively the FINE treatment. The results were similar in both fields. A medium crude protein content of around 10.5% was measured at the 160kg/ha N treatment variants. Also in this setting results were very similar in both fields.

Yield t/ha

The FINE application delivered the highest yields in both fields.

Field Tivans – cultivated, SNS = 56 kg/ha, mean yield 7.02 t/ha

Field Footpath – no tillage, SNS = 71 kg/ha, mean yield 7.43 t/ha

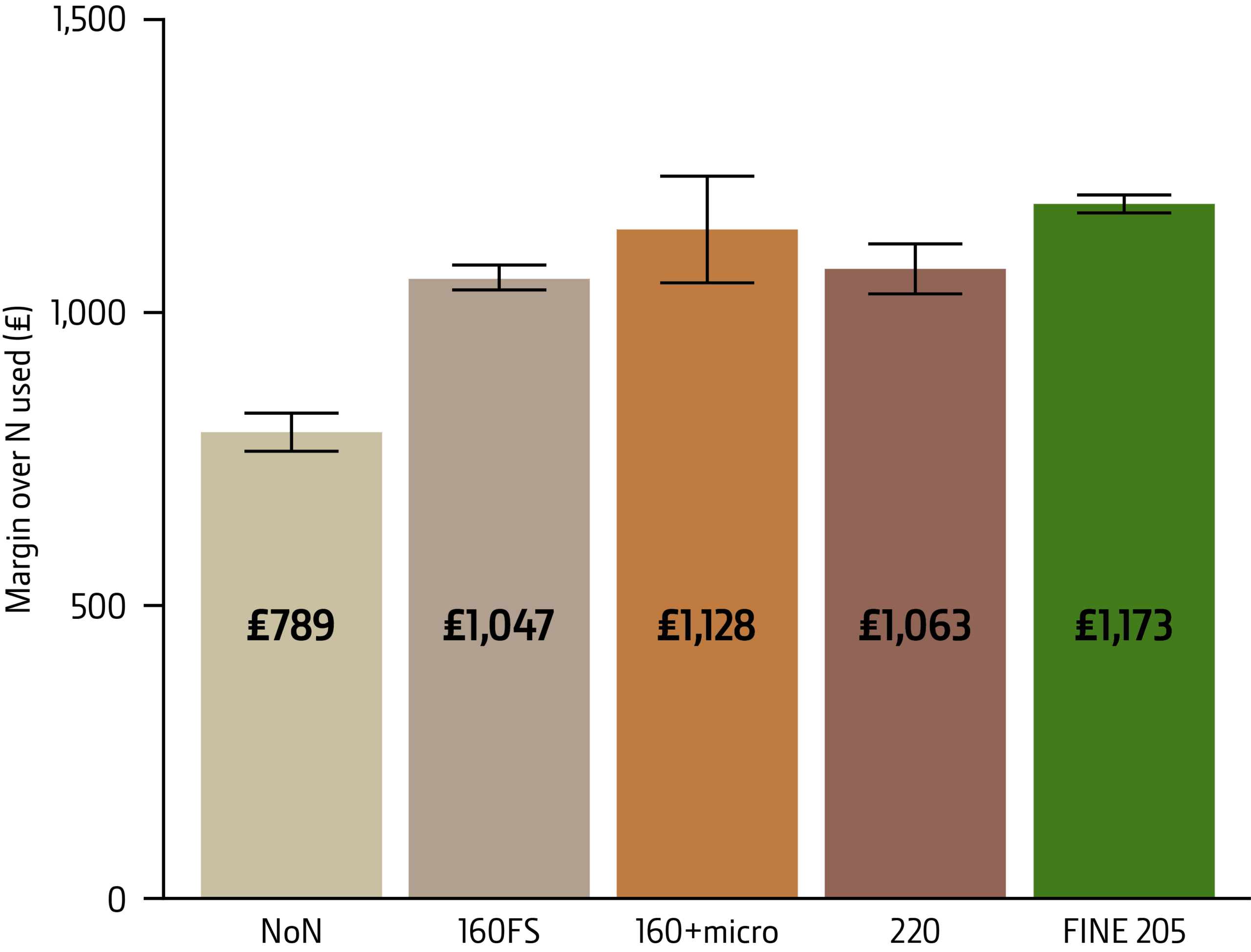

The economic perspective

However, what really counts for the farmer is the net profit. “We are looking for an economic optimum,” explains Carl. The wheat price was at £160/t (€182/t) and the nitrogen cost at £360/t (€410/t). To get an idea of the application which delivers the best economic outcome, the margin over nitrogen costs is calculated, comprising the revenue from grain sales minus the cost of the nitrogen fertiliser. Here, the 160kg/ha N plus micronutrients package and the FINE application in the ‘Footpath’ field stood out.

Margin over nitrogen cost £

The best economic results were delivered by the 160kg/ha N plus micronutrients package and the FINE application.

Field Tivans – cultivated, SNS = 56 kg/ha, mean yield 7.02 t/ha

Field Footpath – no tillage, SNS = 71 kg/ha, mean yield 7.43 t/ha

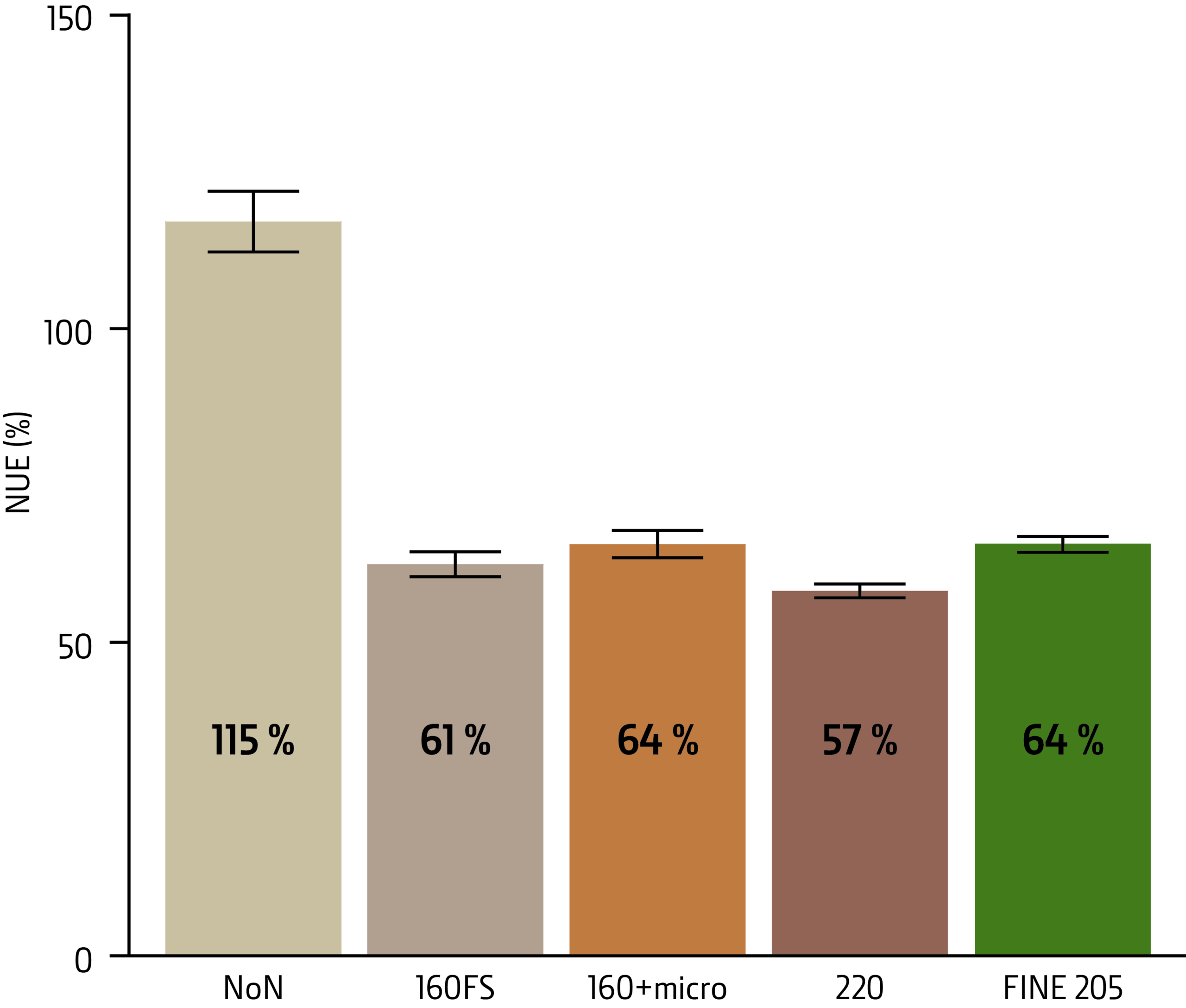

Nitrogen efficiency (NUE)

To build confidence in the accuracy of John Deere’s technology, measurements from an on-board as well as a stationary turn table HarvestLab NIR-sensor were compared with lab results obtained from industry-standard devices “We have run linear regression analysis on the data and found strong correlations between HarvestLab readings and lab results, showing that HarvestLab delivers reliable, real-time protein measurement,” says David. “This makes it a valuable tool for precision nitrogen management as well as for the segregation of milling wheat loads, which can earn the farmer a premium of £20–£50/t,” he explains.

NUE %

The plot with 160kg/ha of nitrogen plus micronutrients proved to be particularly efficient in utilising the nitrogen provided.

Field Tivans – cultivated, SNS = 56 kg/ha, mean yield 7.02 t/ha

Field Footpath – no tillage, SNS = 71 kg/ha, mean yield 7.43 t/ha

But coming back to efficiency; as expected, the highest NUE at over 100% was observed in the plots which didn’t receive any fertiliser, because additional soil nitrogen is mobilised during the growing season. However, this method also delivers the lowest economic results and removes nitrogen from the field, thus depleting the soil nitrogen stock in the long run. As with the economic assessment, the plots with 160kg/ha of nitrogen plus micronutrients proved to be particularly efficient in utilising the nitrogen provided. A possible explanation is the role of molybdenum for nitrogen management in the plant. A similar NUE can be achieved by the FINE set-up.

“Obviously, not applying nitrogen does not make sense for the farmer, but if we use nitrogen intelligently, as our calculations show, farmers can achieve considerably higher profit margins,” says David.

About Ben Burgess

Ben Burgess is still very much the family-run business it was in 1963, as one of the two original John Deere dealers. At that point it had been serving agricultural customers in East Anglia since 1931 and started supplying ground care equipment in 1962.

It has dedicated teams serving a mix of customers throughout Norfolk, Suffolk, Cambridgeshire, Essex, Bedfordshire, Northamptonshire, Lincolnshire and Rutland. These include a 14-strong Precision Technologies team helping customers to optimise their machines for a more sustainable and profitable way of farming with industry-leading technologies.

Ben Burgess also supplies other premium brands including Väderstad, Kramer, Grimme, Kuhn and Timberwolf; complementing the John Deere range, and focuses on offering a high level of expertise and excellent standards of customer service across the group.