Mr Ramstetter, you’ve been with John Deere for over twenty years and have worked at the Zweibrücken plant since 2019. Why is quality so crucial in the combine sector?

Because combines are often only in use for 30 days a year – but during that short window, they must perform flawlessly. Harvest time often lasts just two or three weeks, when the machines run around the clock. Climate change has narrowed these windows even further as crops ripen faster and farmers cannot afford for the machine to be down for even a single day.

When a combine stands idle, the losses are significant. Unlike tractors, harvesters are not easily replaced, few farmers own more than one. That’s why we do everything possible to prevent a standstill from occurring.

We are responsible for the quality of the machines here at the plant, and therefore the customer is our top priority and comes first.

Georg Ramstetter, Production Planning Manager at the Zweibrücken plant

What specific actions do you take in quality assurance?

Our work spans key areas – quality planning, process monitoring, error analysis, and continuous improvement. We collaborate closely with the design department and conduct training to proactively prevent errors. Regularly sessions keep employees in production and service up to date on new technologies. Customer feedback is also central to our process. It helps us ensure that our machines exceed expectations in quality and performance.

How do you utilise customer feedback?

We want to know exactly what matters to our customers. We regularly survey them and review warranty feedback and complaints. Dealers also perform detailed pre-delivery inspections, providing valuable feedback before a machine even reaches the field. Our teams monitor this process closely. We collect and analyse all feedback both positive and negative to identify areas for improvement and to evaluate our machines’ performance. This also helps us better understand our customers’ needs and continuously refine our products.

And then what happens with this feedback?

Depending on the issue, we consult with the relevant department. For instance, if a discharge pipe does not extend far enough, we discuss the design team to determine the cause; if an engine causes problems we reach out to the supplier. Many of our employees come from farming families, so they first-hand how the machines are used and what functions are particularly important. That experience is invaluable – it connects craftsmanship with practical understanding.

Here, a robot welds the side wall of a combine harvester:

Which standards and tools support you in ensuring quality?

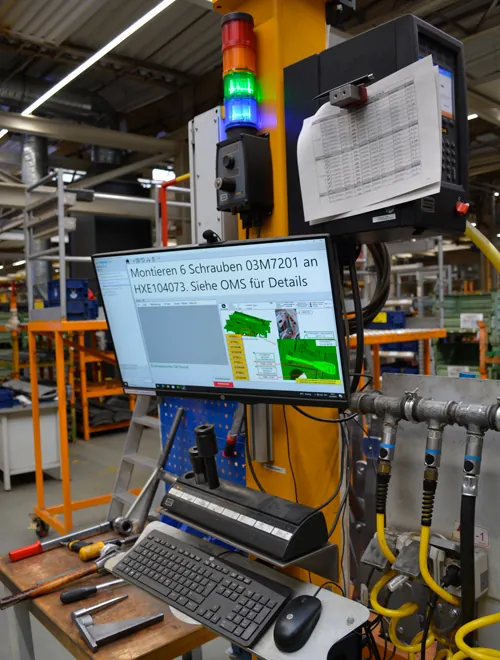

We use a range of advanced tools for assembly, error detection, and documentation. One of the most important is JDAAT (John Deere Assembly Assist Tool), software program which guides operators through every step. It monitors torque, displays work instructions, highlights special features of each machine and confirms successful completion with a green signal. Camera systems track each step, ensuring precision.

Another important tool is TRIS – the Tracking Realtime Information System. TRIS documents every production stage and stores all customer-specific details. This allows us to trace whether any components have been replaced or if any anomalies occurred. Even years later, we can retrieve complete production data making TRIS indispensable for long-term quality assurance. In addition, a variety of digital and mechanical systems help us assemble weld, and test highly complex machines safely and accurately.

Why is your work in quality assurance personally important to you?

Ultimately, we all want food on our tables. Our green and yellow machines play a crucial role in making this happen by reliably supporting farmers during harvest. Knowing that my work contributes to something so essentially makes me proud every single day.

Tools that safeguard quality at the Zweibrücken plant

- Electronic torque and angle screwing systems

- Cameras that ensure the correct tool is selected

- Robotic welding

- Ultrasonic weld-seam testing

- Gas flow monitoring in robotic systems

- Smart Test: electronic testing tool for checking software and electronic components

- TRIS system: tracks every order detail; machines are released only when no errors remain, ; particularly helpful when parts are missing.