“My father is enthusiastic about technology, sensors, and artificial intelligence (AI),” says Moritz Hentzschel at the renowned Fruit Research Station in Jork on the Lower Elbe in Germany. “It provides reliable information from large amounts of image data and may soon be used on his fruit farm in Rödinghausen, North Rhine-Westphalia.” Moritz himself does not intend to take over his parents’ berry and pome fruit (for example, apples and pears) business, but as a trained horticulturist, he is involved in the Samson research project. This looks at smart automation systems and services for fruit growing in the Lower Elbe region, and sees him working with various AI technologies that, while not yet implemented in practice, could soon become relevant for fruit growing.

New research on AI in fruit growing

The 26-year-old’s colleague, David Berschauer, is a research associate at the Fraunhofer IFAM, which leads the project leader in Stade, and is concurrently pursuing a master’s degree in computer science at HAW Hamburg. Given the project’s significant progress and the delivery of important new insights, it is likely to continue receiving federal funding beyond the end of the current round in 2025. “We are confident that our work on AI in fruit growing will continue,” says David, looking optimistically to the future.

We continuously train the AI models so that the results determined by the software are ultimately reliable and relevant for the fruit grower.

David Berschauer, research associate at the Fraunhofer IFAM

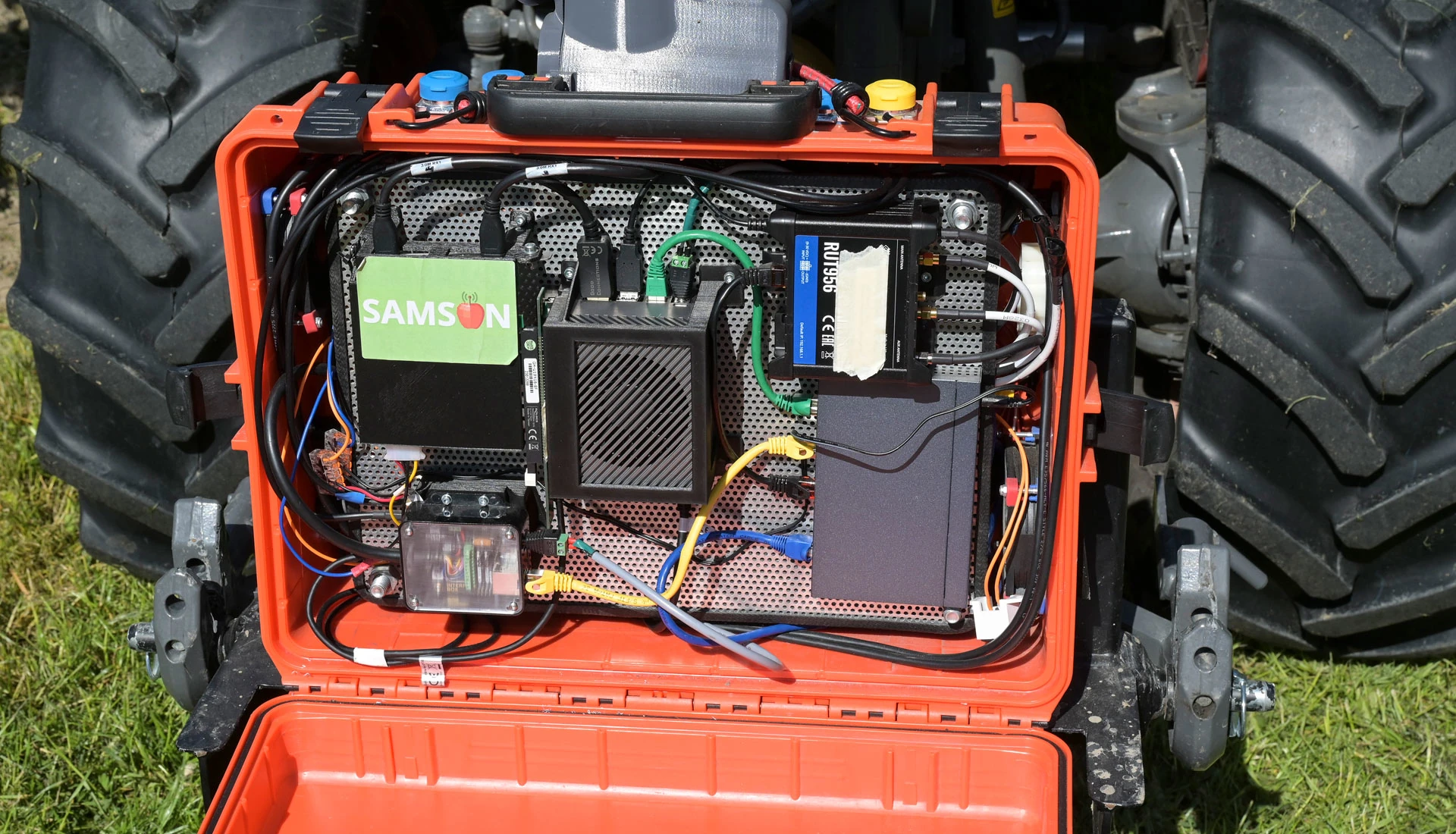

He is happy to explain the technology used: At its core, it is a sensor box that is mounted in front of a tractor’s bonnet, which the researchers use to make their rounds in the crop. The box contains a lidar sensor that precisely measures leaf surfaces as well as two RGB cameras, which each capture five images per second with a ‘stereo effect’ and generate up to 400MB of data per second. “This is too much, and is not yet practical in the long term,” David points out. It is clear that the Samson team can use real-time kinematics (RTK) to precisely locate every movement of the cameras on each individual tree in the stand to within a few millimetres.

This is also essential because the imaging process, paired with the AI behind it, requires this degree of accuracy to ultimately deliver usable, insightful data. Data which, it should be emphasised, could also be determined by the experienced, trained eye of a fruit grower — if they actually had time for each individual tree. This includes the optimal harvest time and a precise forecast of the expected harvest quantity and qualities. The latter is crucial information for timely marketing of the fruit.

So how does the AI work?

“We feed the acquired image data into our software, which processes it in a neural system with several million parameters,” explains David. “We continuously train the AI models so that the results determined by the software are ultimately reliable and relevant for the fruit grower.” Since this data is becoming increasingly important in a competitive environment, AI is now being introduced at a rapid pace and with full power to agricultural operations following remarkable advancements in automation, GPS, and robotics. The opportunities are substantial, and the enthusiasm is sometimes even greater. However, there is also significant scepticism towards a development that undoubtedly possesses revolutionary potential and will permanently transform work on farms.

But back to Samson and fruit growing: Data collection via sensors is one side of the coin. Processing the data meaningfully is the other, equally important aspect. This requires training. Training is currently making rapid progress so that individual crop management for each tree will eventually be possible. What humans cannot achieve despite their greatest efforts — simply due to a lack of time — is accomplished by the computing power of hardware. Ultimately, with the help of AI, the spray nozzle opens for wide-ranging crop protection, or frost protection is only applied when it is truly necessary. This saves resources and protects the environment. One example is frost protection: Currently, when night frosts are expected, many apple orchards are irrigated in order to avert potential damage. Often, even when temperatures below zero degrees Celsius are forecast, they do not actually reach the dangerous frost level. This incurs significant costs (40,000l/ha are used per hour of frost protection), which AI, fed with extensive weather data and additional information on the crops, reduces to the bare minimum.

Nonetheless, AI also comes at a price. It incurs costs in terms of development, installation, and energy consumption. It must therefore be cost-effective if it is to be implemented, although young researchers like David and his colleague Frederick Blome claim that yield increases of 20-30% can be expected. Providing the fruit grower remains in control and the AI application is easy to use, David has no concerns: “The risks are clearly calculable”.

Weed detection made easy

Samson in fruit growing is like Sam-Dimension (smart aerial mapping) in arable farming: At 8am in sunlit June, a John Deere tractor pulls a field sprayer through an onion field in Armstedt, Schleswig-Holstein. Tjark Hartmann-Paulsen from the Hof Hasenkrug farm grows red and white onions on a 15ha plot for the Edeka retail chain. There is nothing particularly remarkable about the scene itself. But that is deceptive. This is because an AI-based system from the Stuttgart-based start-up Sam-Dimension GmbH is being used for crop protection by contractor Jan Marten Scheel from Sarlhusen.

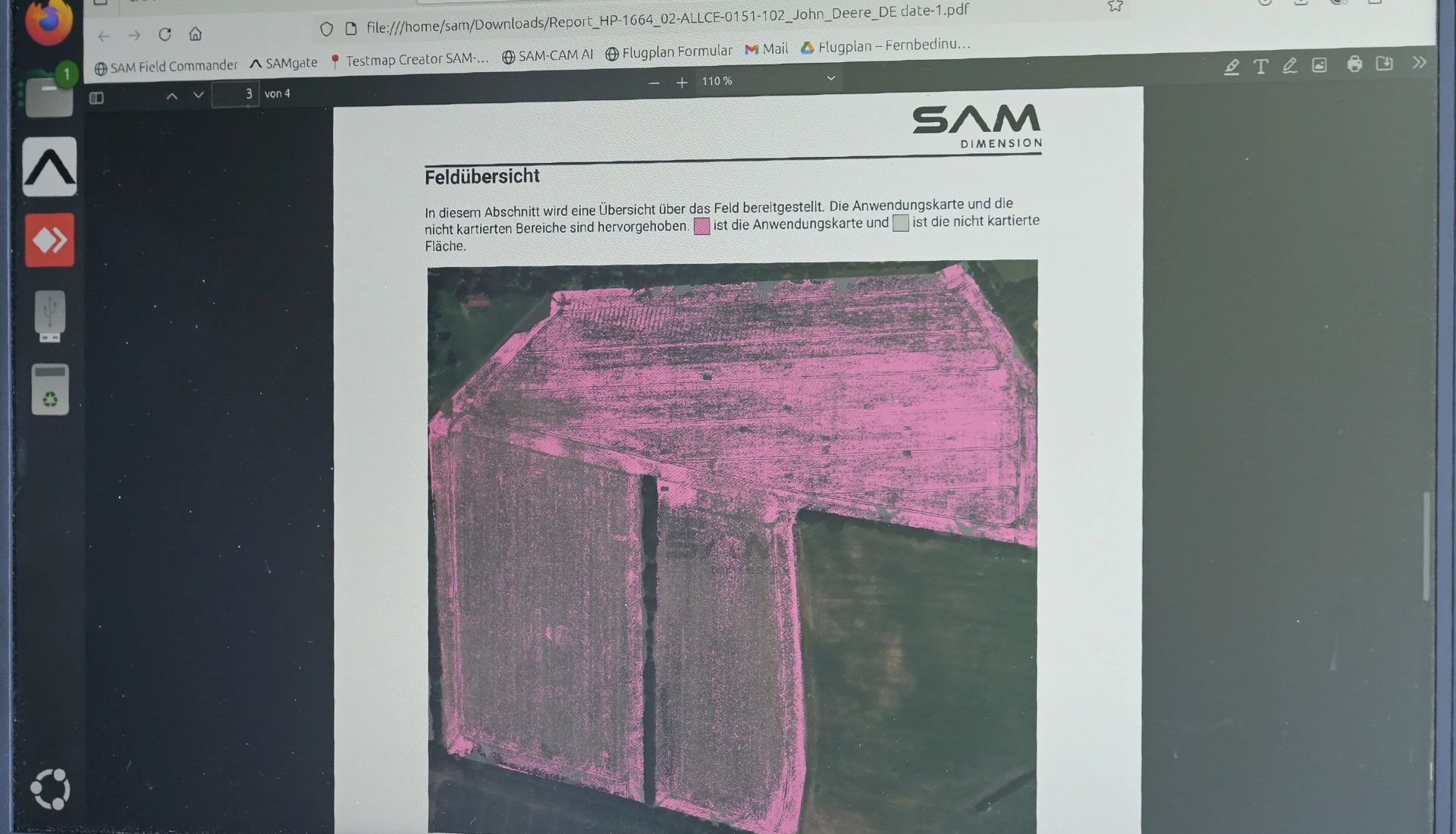

The entire onion field has already been surveyed by a drone, which captured the whole site in detail with a camera. The drone operates at an altitude of approximately 60m, capturing six images per second. It requires about 15 minutes to cover the 15ha. The generated image data package has a volume of several hundred gigabytes, which is pre-processed in the field and then sent to the Sam central computer. On this computer, AI-based software processes the flood of images and identifies weeds and unwanted grasses at incredible speed. Lastly, the AI-based software generates a field map with a small data volume, which is sent back to the contractor and then imported to the tractor or sprayer.

Previously I applied the same spray rate across the entire field, with this system it’s only about a fifth.

Tjark Hartmann-Paulsen, farmer

This field map shows exactly where the weeds are. In conjunction with the John Deere GPS system and a sprayer with PWM, the Sam application map enables pinpoint, highly accurate, and targeted spraying. This saves chemicals. “Where I previously applied the same spray rate across the entire field, with this system it’s only about a fifth, simply because there is no weed pressure in many places and the technology informs me of this,” says Tjark.

Contractor Jan is the first in Northern Germany to utilise drones and AI-based data collection. This is all still quite new to the 26-year-old, but he is convinced by Sam and AI systems. He believes it is the future. “I have invested a substantial five-figure sum in this,” says the innovative contractor. “That includes the drone as a carrier platform for the Sam-Cam AI mapping camera, as well as the complete software to use the Sam Dimension system and the data processing for map production.” He charges farmers for his additional service by hectare and crop type — for onions, the cost is €35. Smiling, he adds: “It’s a win-win for everyone.”

And what does the future hold for AI in agriculture?

It is not yet clear how and where AI will ultimately take root. Will it make work on farms easier and better or rather more complicated? Lea Fliess, managing director at Forum Landwirtschaft (FML), an association of over 60 members from the agricultural sector, has a clearly positive position on this: “Whether AI is a curse or a blessing for the agricultural sector depends on how we use it. If it is developed together with farmers — and in dialogue with society — its full potential can be realised,” he says. “Trust can only grow if people understand how AI operates in the field and the contributions it makes to the environment, animal welfare, and nutrition. When used correctly, it saves time, reduces operating resources, and opens up new opportunities for sustainability. Achieving this will require active planning: Rooted in practice, responsibility and political backing.”