Bernd Bund’s farm lies in Hesse, a German federal state in the middle of the country. Together with another farmer, he harvests almost 500ha of arable land as part of a machinery co-operative. His crop rotation includes winter wheat, winter and spring barley, rapeseed and peas.

Protein content in focus

Mr Bund markets his wheat through the regional agricultural merchant. Depending on the market situation and his own expectations, between 20 and 60% of the milling wheat is pre-contracted annually.

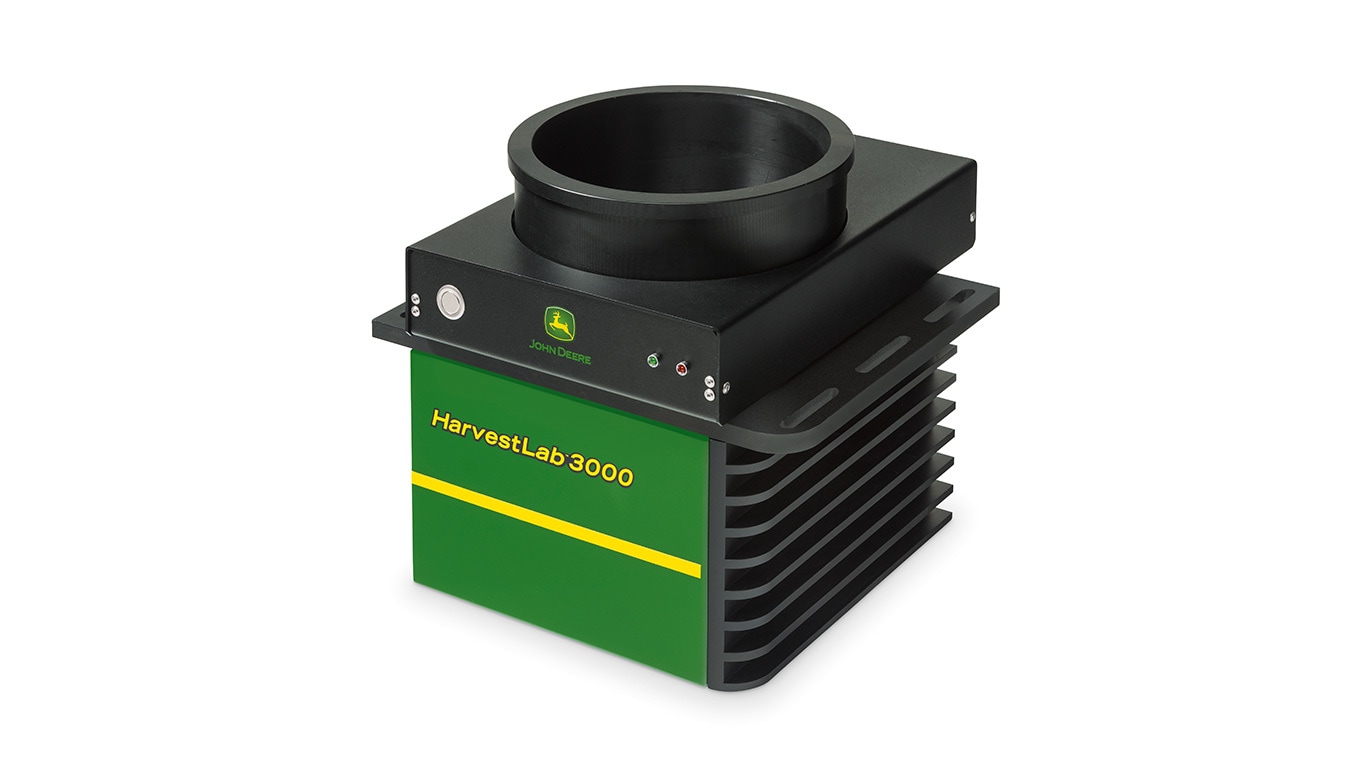

Today, Mr Bund no longer wants to do without the information provided by the HarvestLab 3000 NIR sensor.

Protein content is the most important parameter when it comes to marketing. By using near-infrared (NIR) spectroscopy the HarvestLab 3000 sensor from John Deere provides him with this data instantly during harvest. For this purpose, the NIR sensor is mounted to the side the John Deere S780i combine.

This is exactly the information to help us.

Bernd Bund

In 2021, Mr Bund used the NIR sensor for the first time. Previously, the protein content in wheat during harvest was a “black box” for him. To analyse protein levels, a farm worker had to take a wheat sample to the grain merchant. It took about 2.5 hours until the result was finally available. “By then, we were already harvesting in another field and the conditions were different,” he explains.

Harvest Lab 3000 also provides the farmer with wheat moisture data. Comparing the values with those measured by manual devices on his farm, he believes that the sensor provides more precise data. For Mr Bund, however, moisture measuring is only of secondary importance. For him, the focus is on the quality of his grain.

HarvestLab 3000

Near-infrared (NIR) spectroscopy to analyze various constituents within harvested crops, silage or slurry (one sensor, three applications)

Exploiting the economic potential

“In the past, as soon as the wheat was in storage, I could no longer separate it and therefore I could not exploit the economic potential,” explains Mr Bund. “We also do not have the storage capacity to separate batches of wheat on spec. This used to be a problem for us. We could not achieve a premium for higher wheat quality.”

Today, batches are separated according to quality criteria during the harvesting process and unloaded onto different trailers. This helps a lot with marketing, but clear documentation is crucial.

Mr Bund can call up the protein content data directly from the John Deere Operations Centre while viewing it simultaneously on the PC or smartphone. The latter he finds particularly useful. This allows him to view the data easily and intuitively at the touch of a finger and decide which box to put the respective charge. “This is exactly the information that I didn’t have before and that now takes us a good step forward”, he says.