Christoph Hante is a farmer and contractor through and through. “When I was a schoolboy, I preferred to work in the fields, so I left a few homework assignments undone every time,” he laughs. While training as a farmer, he was already working as a driver at his parents’ contracting company, and quickly discovered his love for handiwork and tinkering.

In 2019, he took over contracting company Hante Agrarservice GmbH, as well as the family farm. He is restructuring these together with his father Heinrich Hante: “With my motivation and expertise in the technical field, we decided to give up the 1,000-head pig farm. Instead, we wanted to concentrate more on the contractor part, and work on our unique selling proposition; liquid manure spreading with the strip till.”

„No mineral fertiliser anymore“

Farmer and contractor Christoph Hante about in-soil fertilisation with strip till

Tinkerer instead of theorist

For Mr Hante, the story of the strip till process began as far back as 2012. Because 60ha of the Hantes’ fields are in a water protection area, he keeps in close contact with the local waterworks and is working on reducing nitrate leaching into the groundwater. “The easiest way is to apply less nitrates – but we don’t want to lose yield either. This means that we have to apply the fertiliser more efficiently.”

We asked ourselves how we can reduce nitrate leaching into groundwater, without losing yields.

Christoph Hante

Then, at Agritechnica, there came a flash of inspiration: Kuhn presented the Striger strip till. Combining in-soil fertilisation –with strip tillage could help spread slurry efficiently and avoid losses. “Most of the people that we spoke to said it would be too difficult or too time-consuming,” says Mr Hante. “That really motivated me to keep working on this concept.”

Success across the board

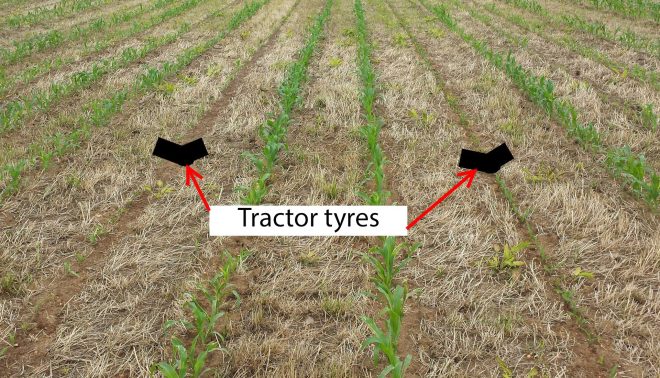

Ten years later, Mr Hante has achieved series production with his modified Striger. The most important adjustment along the way was offsetting the frame by exactly 37.5cm so the wheels drive between, and not over the seed rows. “The fact that we don’t drive over the rows was certainly one of the reasons behind our rapid success. The results can be seen immediately in the uniform emergence and development of the plants.”

Mr Hante’s strip till works as follows: The eight-row Kuhn Striger hangs behind a Briri pump tanker filled with liquid manure. At a row spacing of 75cm, the soil is loosened to a width of around 20cm and a depth of 25cm. A liquid manure strip is then injected at a depth of 12-15cm. The seed, usually maize, is later planted in the same strip and then can feed on the liquid manure. “Basically, we use the strip till like a drill – only using a slurry tanker.”

Precision leads to achieving the goal

For sowing to be successful, precision is of particular importance. The maize seed must be placed exactly on the liquid manure strip in order to achieve good yields. That is why Mr Hante has been using John Deere’s AutoPath GPS-controlled steering system since 2021. It records the track of the strip till when spreading liquid manure and uses this information again when planting maize with the drill. This means each seed is then laid on the liquid manure strip to an accuracy of 3cm. The recorded lane is also used when hoeing with the boulder pickaxe. Mr Hante can therefore drive and hoe right between the rows – without risking yields.

With AutoPath, we record the track of the strip till when spreading liquid manure and apply it again when laying maize.

Christoph Hante

As a result, the plants are better supplied with nutrients; the maize stays green longer and the cob and flag don’t grow apart as quickly. “This means that the time for pollination is longer.” The reduced tillage also reduces water loss from the soil, there is less erosion, and the ground between the seed rows is much easier to drive on in autumn.

According to Mr Hante, farms with pigs and biogas plants particularly benefit from the strip till process. “Farms that weigh the grain report back higher yields to us, even though they use less mineral fertiliser. Biogas plants measure a higher nutrient content in strip till maize – with one customer reporting 0.2 to 0.3 megajoules.”

The biggest advantage of the strip till is its efficiency. Farmers save on liquid manure, of which they can spread les – and two-thirds of Mr Hantes’ customers can now completely do without in-soil mineral fertiliser, without impacting yields.

The facts and figures clearly speak in favor of the strip till method, especially when planting maize. “Nevertheless, in agriculture, feeling counts more for many people,” says Mr Hante. “Even if there is a great number on the scales at the end, many say: ‘Yes, but the corn from the neighbours still looked better’.”

That’s why he would like to see even more openness on the part of customers: “Anyone who wants to use the strip till process has to plan more. I hope that additional farmers will take the trouble in the future as the legal requirements (over environmental protection) are increasing anyway, and everyone benefits from the efficiency of the process.” Mr Hante also has one wish for John Deere: “It would be great if the combination of tractor, liquid manure spreader and strip till could work the areas completely autonomously.”

Hante & Hante Agrar

Christoph Hante is a partner in Hante Agrarservice GmbH. In 2022, the family-run contracting company had six permanent employees and between 15 and 20 temporary workers during the season. The Hante Agrarservice fleet includes nine tractors, three combines, two forage harvesters and a baler from John Deere, as well as three strip tills, all of which are equipped with the AutoPath. The contractor’s focus is on liquid manure fertilisation, but services also include grain and maize harvesting, tillage, silage and straw collection.